Contact via WhatsApp

Contact via Email

Fully Automatic Plastic Recycling Plant Manufacturers in Vapi

Ansari Machines leads the market as one of the foremost Fully Automatic Plastic Recycling Plant Manufacturers in Vapi . With a commitment to innovation and sustainability, we produce cutting-edge Fully Automatic Plastic Recycling Plant that redefine plastic waste management. Our state-of-the-art manufacturing facilities and skilled workforce ensure precision engineering and durability in every plant. Trusted by industries nationwide, Ansari Machines continues to set the benchmark for excellence in Fully Automatic Plastic Recycling Plant manufacturing, delivering solutions that optimize resource recovery and promote environmental conservation.

Fully Automatic Plastic Recycling Plant Suppliers in Vapi

As a trusted supplier of Fully Automatic Plastic Recycling Plants in Vapi, Ansari Machines offers a comprehensive Fully Automatic Plastic Recycling Plants to meet diverse industry needs. With a focus on quality and customer satisfaction, we provide efficient and reliable solutions for plastic waste recycling. Our extensive network of distribution channels ensures prompt delivery of our products to customers across the country. From small-scale operations to large industrial setups, we cater to the requirements of various industries, driving efficiency and sustainability in waste management processes.

Fully Automatic Plastic Recycling Plant Exporters in Vapi

Ansari Machines stands as a leading Fully Automatic Plastic Recycling Plant Exporters in Vapi . With a strong foothold in international trade, we serve clients worldwide with top-quality Fully Automatic Plastic Recycling Plant that meets global standards. Our Fully Automatic Plastic Recycling Plant are renowned for their reliability, efficiency, and durability, making them the preferred choice for Fully Automatic Plastic Recycling Plants in Vapi. From recycling facilities to manufacturing plants, our Fully Automatic Plastic Recycling Plants are engineered to deliver superior performance, contributing to sustainable waste management practices on a global scale. Trust Ansari Machines for innovative Fully Automatic Plastic Recycling Plants in Vapi.

Fully Automatic Plastic Recycling Plant

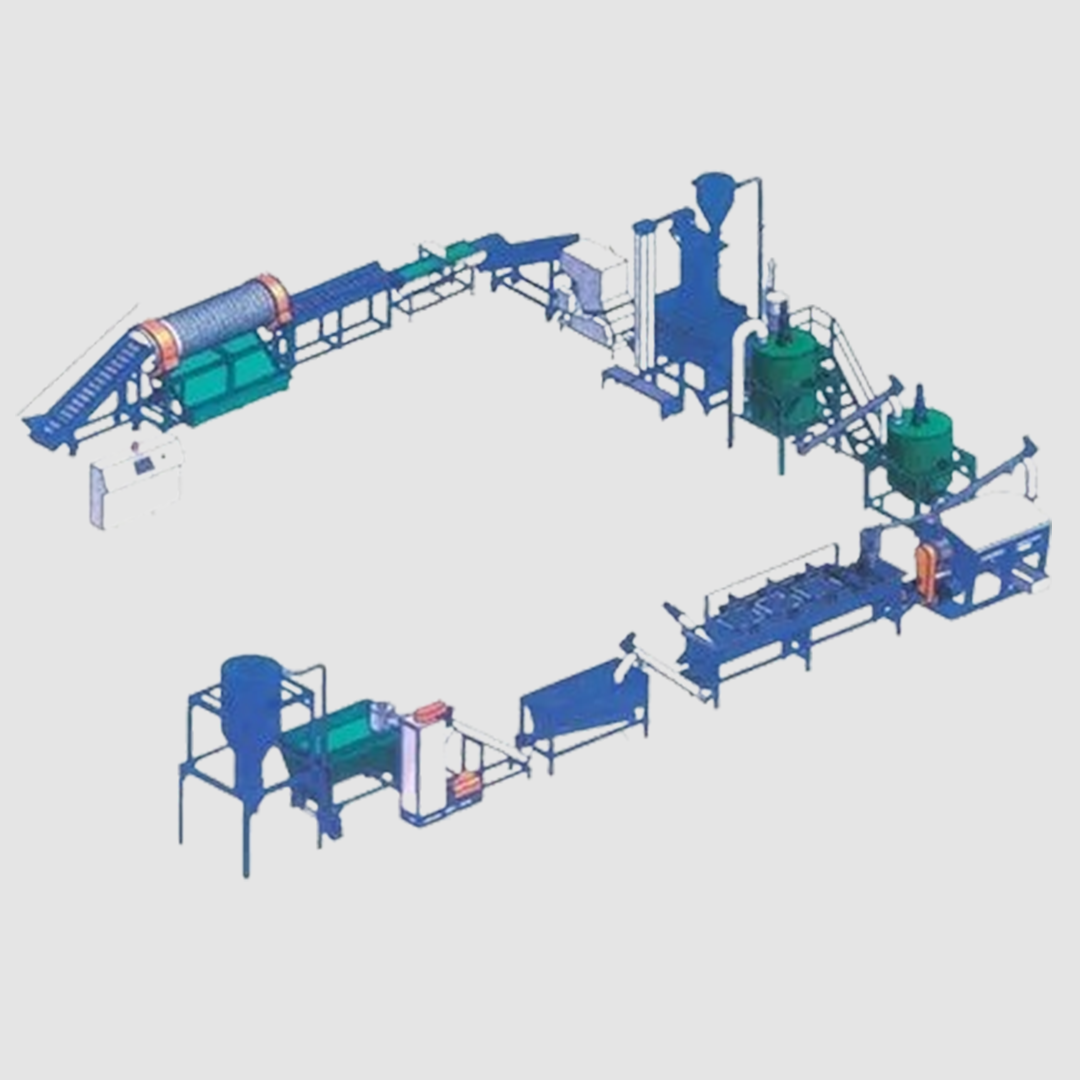

Our Fully Automatic Plastic Recycling Plant automates all stages of plastic waste recycling, from sorting and cleaning to shredding and pelletizing. Designed for minimal manual intervention, this plant ensures high efficiency, consistent output, and reduced labor costs. It features advanced technology, robust construction, and energy-efficient operation, making it ideal for large-scale recycling operations. This plant supports sustainable waste management practices by converting plastic waste into valuable raw materials. With its reliable performance and low maintenance needs, it is a cost-effective and environmentally friendly solution for modern recycling facilities.

A plastic recycling plant is a facility that processes plastic waste to produce reusable plastic material. The plant utilizes various technologies and processes to sort, clean, and process the plastic waste before transforming it into new products. The working principle of a plastic recycling plant involves several key steps that ensure the efficient recycling of plastic materials.

Sorting and Collection

The first step in the working principle of a plastic recycling plant is the sorting and collection of plastic waste. This involves separating different types of plastic materials based on their resin codes and colors. The collected plastic waste is then transported to the recycling plant for further processing.

Shredding and Washing

Once the plastic waste is collected, it undergoes shredding and washing processes. The plastic materials are shredded into small pieces to increase the surface area for better washing and cleaning. The shredded plastic is then washed to remove any impurities such as dirt, labels, and contaminants.

Drying and Pre-Heat

Plastic dryer machines use centrifugle force principle to dry plastic pellets or granules. Blades remove plastic from the shaft, distribute air evenly, and release moisture through an exhaust system. The material is then pre-heat in a plastic mixer machine with rotating blades or paddles. The heated material becomes softer and moisture-free, ready for extrusion.

Melting and Extrusion

After washing, the clean plastic pieces are melted down in a process called extrusion. The melted plastic is then formed into pellets or sheets, which can be used to manufacture new plastic products. This step helps in reducing the energy consumption and carbon emissions associated with traditional plastic production.

FAQs about Working Principle of Plastic Recycling Plant

1. How does a plastic recycling plant contribute to reducing plastic pollution?

Plastic recycling plants help in transforming used plastic materials into new products, reducing the demand for virgin plastic and lowering the overall environmental impact of plastic waste.

2. What are the key steps involved in the working principle of a plastic recycling plant?

The key steps in the working principle of a plastic recycling plant include sorting and collection, shredding and washing, melting and extrusion, and final product manufacturing.

3. How does the recycling of plastic waste benefit the environment?

Recycling plastic waste helps in conserving natural resources, reducing energy consumption, and decreasing environmental pollution caused by plastic waste.

4. What types of products can be manufactured using recycled plastic material?

Recycled plastic material can be used to manufacture a wide range of products, including plastic containers, packaging, textiles, and building materials.

5. How can individuals support plastic recycling efforts in their communities?

Individuals can support plastic recycling efforts by properly sorting and disposing of their plastic waste, advocating for sustainable solutions, and raising awareness about the importance of recycling.